UNDERSTANDING YOUR VEHICLE'S CHASSIS

|

CHASSIS EXPLANATION A vehicle’s chassis is the main structure of the vehicle, where all other components are assembled to it. Each vehicle’s attributes are designed to satisfy the requirements of a desired group of end users. NORMAL PASSENGERS CARS Normal passenger cars are formed with a few common goals in mind; comfort being one of them. In order to achieve this, a set of street-use suspension and soft-rated springs will be chosen by the vehicle manufacturers. Although maintaining comfort levels, the vehicle sacrifices its ride handling. The vehicle will have more body roll, especially during emergency stops, which contributes more forces to the front, resulting in poor steering response, stopping power, and can even result in accidents.

|

|

HOW IT WORKS

|

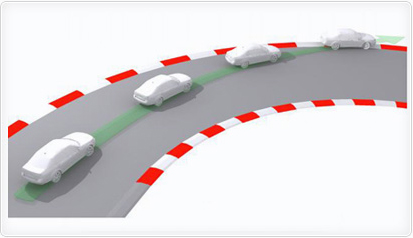

Strut Bars and Chassis Strengthening Technology: If you’re serious about your car’s handling performance, you'll probably be interested in lowering the suspension. In most cases, unless you’re a complete gear head, this will be more than adequate. However, if you are a keen driver, you will be able to get far better handling out of your car by fitting a couple of other accessories to it. The first thing you'd invest in is a front strut bar. When cornering a turn, the whole car’s chassis is twisting slightly. In the front (and occasionally in the rear), the suspension pillars will be moving relative to each other because there’s no direct physical link between them. They are connected via the car's body, which can flex depending on its stiffness. A front strut bar bolts on top of the strut towers, creating a sturdy bridge that suspends over the engine. The result is that the whole front suspension setup becomes a lot more rigid, and there will be virtually no movement relative to each side. It's as if you’re adding the fourth side to the open box that is your vehicle's chassis. Is there a need to have my vehicle's chassis strengthened? The chassis of the car experiences the most abuse from the driver. It is particularly due to the weight transfer of the vehicle body during fast cornering, hard braking, or hard acceleration. In some instances, the weight transfer during cornering may cause one side of the vehicle to experience as much as 3 times more force than the other side of the vehicle, causing enormous chassis flex/vehicle body deformity, consequently causing tires to lose grip. Deformity and twisting of the vehicle chassis during cornering may cause negative handling traits such as under-steering and over-steering.

|

WHAT IS VEHICLE HANDLING?

|

UNDER-STEER Under-steer is a condition where, while cornering a turn, the front tires begin to slip. With the front tires broken loose from the road and the rear tires continuing to grip, the vehicle will ultimately turn less than desired. The front wheels lose their traction and won’t turn any sharper, even when the steering is being corrected to turn the car more. This will cause the car to go wide instead of following the turn. The dangers of under-steer lead to your vehicle running off the road, possibly hitting obstacles or other vehicles. Under-steer occurs in front-wheel-drive vehicles more often than in rear-wheel-drive vehicles. Car manufacturers employ the FF (front-engine, front-wheel-drive) setup in modern cars for improving driver and passenger safety. The natural behavior of an FF car causes it to have inevitable under-steer due to its heavier front end. Under-steer can be corrected by stiffening the rear end of the vehicle by adding a rear strut bar and a rear anti-roll bar. |

OVER-STEER Over-steer is the direct opposite of under-steer. The front tires continue to grip the road and complete the turn while the rear tires break loose. This causes the rear of the vehicle to kick out, turning the front of the vehicle into the turn even further. Over-steer occurs in rear-wheel-drive vehicles more often than front-wheel-drive vehicles. Sometimes over-steer is done purposefully, which is called "drifting".

FR (front-engine, rear-wheel-drive) or RR (rear-engine, rear-wheel-drive) cars mostly experience over-steer when cornering. Over-steer can be corrected by stiffening the front end of the vehicle by adding a front strut bar and front anti-roll bar. |

|

|

WHAT AFFECTS HANDLING? When any of the wheels lose contact with the road's surface, there will be a decrease in handling performance. Preferably, we'd like the vehicle to maintain complete contact on the road at all times, but this highly unlikely. Vehicle load, road condition, weather, speed, and many other uncontrollable factors are bound to affect your car's handling. You can be a very experienced driver, but there are just some things that cannot be avoided. |

||

|

|

|

WITHOUT VS WITH A STRUT BAR AND LOWER ARM BAR |

||

|

BEFORE Part of the shock from impact transfers to the chassis, causing wheel housing and lower arm deforming. |

AFTER Once equipped with an Ultra Racing strut bar and lower arm bar, the shock from impact will be neutralized on both sides. |

|

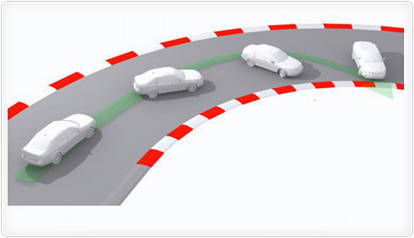

WHILE ENTERING A CORNER |

||

|

BEFORE The weight transfer and force gathers on one side, causing unstable handling and an increase in body roll. |

AFTER Once equipped with an Ultra Racing strut bar and lower arm bar, body roll decreases, which evens out weight transfer. The car is now stabilized through turns and has better handling. |

|

WITHOUT VS WITH FENDER BARS |

||

|

BEFORE The joint between the A-pillar and front of the chassis bends and twists from force of impact and drag force, causing permanent damage to the chassis. |

AFTER Ultra Racing’s fender bar will spread out the force and strengthen the joint, preventing further damage and offering better handling. Recommended for car's with stiff, aftermarket suspension. |

|

WITHOUT VS WITH A SIDE LOWER BAR |

||

|

BEFORE On uneven / bumpy road, center section chassis will have different level of body flex cause by the weight transfer between front and rear. |

AFTER Ultra Racing’s side lower bar will stabilize the weight transfer between front and rear, it can also minimize the damage from side impact. |

|

WITHOUT VS WITH

|

||

|

BEFORE When cornering a turn, the transfer of weight will make the car sway to one side, causing body roll and difficulty turning, weakening the steering response. |

AFTER The upgraded version of Ultra Racing’s anti-roll bar will be more effective in preventing the car from swaying through corners, greatly reducing body roll and enhancing stability/handling. |

|

DESIGN & MATERIAL |

||

|

||

|

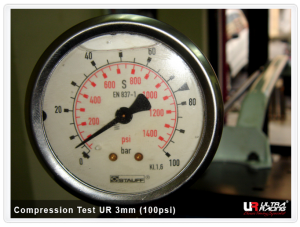

In order to reach the desired performance of Ultra Racing products, we constantly monitor the quality of our bracing, not only during the production stage, but also by conducting strict performance testing. During the development phase of Ultra Racing bars, we ensure the products are in accordance to our design and development philosophy. We conduct real, on-road performance tests as well as on-track tests. To obtain data, we also invented three testing jigs: the compression test jig, torsion test jig, and flex test jig. These jigs are used to test the performance of our products on a continuing basis. For the compression test, forces are applied along both sides of the bar. Maximum compression force is recorded to study the structure of various kind of designs that the bar can withstand under different driving conditions including impact simulating an accident. We use a hydraulic pump to compress at set pressures and record the results For the torsion test, a strut bar is bolted to the jig, then a twisting force is applied to simulate flexing on the chassis. Torque is applied to one side of the bar, and the amount of twist is recorded. The torque applied in the test is fixed at 6.6kg/m. For the flex test, torque is applied on both ends of the bar to simulate another direction of flex on the chassis. The torque applied in the test is fixed at 8kg/m. |

||

RESEARCH & DEVELOPMENT |

||

|

COMPRESSION TESTBrand : UR (Civic EK 2 points) Bracket : Non Adjustable Bracket thickness : 4MM Weight : 3.30LBS (1.5 KG) Compression Impact : 3MM (100 psi) |

|

|

Brand : ??? (Civic EK 2 points) Bracket : Adjustable Bracket thickness : 4MM Weight : 3.08LBS (1.4 KG) Compression Impact : 70MM (100 psi) |

|

|

|

FLEX TESTBrand : UR (Civic EK 2 points) Bracket : Non Adjustable Bracket thickness : 4MM Weight : 3.30LBS (1.5 KG) Flex : 50MM (8 kg/m) |

|

|

Brand : ?? (Civic EK 2 points) Bracket : Adjustable Bracket thickness : 4mm Weight : 3.45LBS (1.4 KG) Flex : More then it should |

|

|

TORSION TESTBrand : UR (Subaru Forester 2 points) Bracket : Non Adjustable Bracket thickness : 4MM Weight : 3.96LBS (1.8 KG) Torsion : 47MM |

|

|

|

Brand : ?? (Subaru Forester 2 points) Bracket : Adjustable Bracket thickness : 4MM Weight : 4.4LBS (2.0 KG) Torsion : 85mm |

|

MATERIAL SPECIFICATION & DESIGN |

||

|

Every materials used are carefully selected to ensure the best performance and safety. The brackets are made of 4MM to 5MM steel plates, while the hollow steel tubes and oval tubes are of 1.2MM to 1.6MM thickness. These materials are selected to ensure the bars are rigid and strong to maintain constant geometry at all times, yet safe enough to crumble during an impact for safety reason All our raw materials has been made and tested with satisfactory result. |

||

|

To achieve safe condition, the displacement must be less than the thickness of the material which is below 2mm. Therefore, the bar is in SAFE condition. |

||

MILL / TEST CERTIFICATE (Chemical Composition)JIS 3101 SS 400 (Japan International Standard) JIS G 3141 SPCC SD (Japan International Standard) ASTM A 500 Grade A (American US Standard) BS 1387 ( British Standard)

|

||

STEEL VS ALUMINUM |

||

|

Why We Use Steel Instead of Aluminum? First, steel is stronger than aluminum for the same size and thickness. In order for aluminum alloys to be at least the same strength as steel, it has to be at least double the thickness (Steel 4MM = Aluminum 8MM). When that happens, weight saving is not so apparent anymore. Of course there are also exotic materials and alloys that can match the strengths of steel, but the cost are astronomically high and therefore not very cost effective to bring into mass production. |

||